- Compliant with Pipeline Hazardous Materials Safety Administration, DOT P173.28

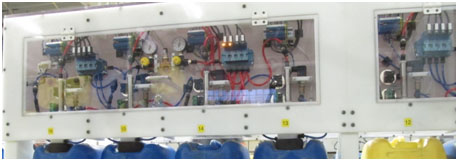

- Computer controlled using 2 networked industrial computers

- Ethernet compatible for remote data acquisition if required

- Password protected

- Each station has on push button and two lights for the operation the test sequence

- Operator instruction listed on the front panel with calibration instructions listed on the monitor panel

- Testing parameters are adjustable i.e. max air pressure and test time

- Both peek cut off pressure and test time can be adjusted in the software

- High accuracy (+-1%) reading with traceability to NIST

- Calibrated digital meter supplied as a reference is supplied with the system

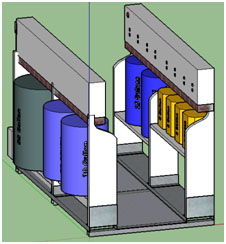

- Primarily designed for 5 & 2.5 gallon car boy containers

- A 16 station tester is capable of testing one every 20 seconds – 180 tests an hour

- Removable EPDM foam test heads

- Capable of data logging

- Run & Estop switches on front panel

- Built in monitor with touch screen input

- Operator protected from automation movement

- Adaptable to 15, 30, & 55 gallon containers – lower output than car boy tests

- Partially sealed cabinets are pressurized to keep corrosive fumes away from sensitive components